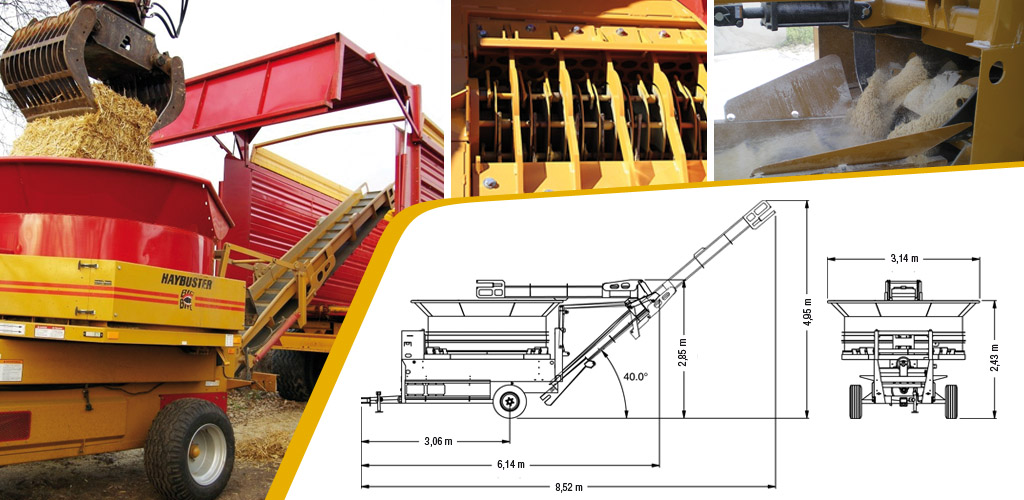

H-835

NEW Side discharge conveyor

Convenient and easy to operate. Allows ground material to be stacked neatly ready for use in a TMR. Less dust produced than when using a blower/spout for discharge.

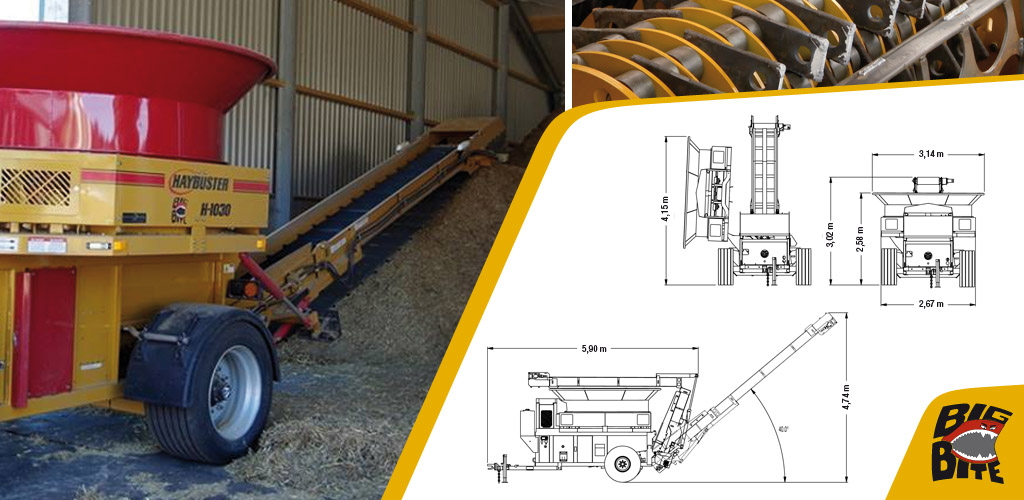

Larger screen area

Screen area has been increased by 25% over pervious model resulting in significantly higher output. Screens can be changed quickly from outside the machine. Range of sieve screens sizes available 10mm to 120mm allowing for very consistent chop length. Option to grind cereals using grain hood.

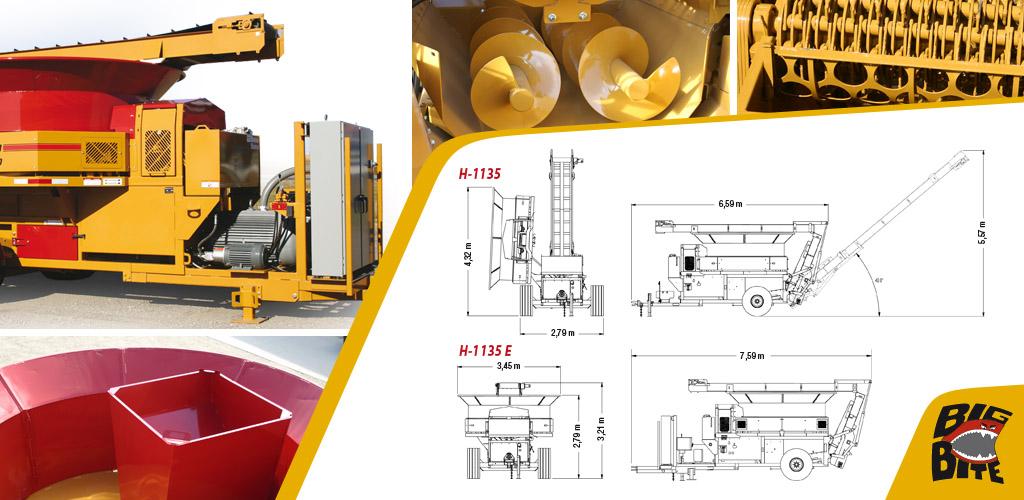

NEW V-Tub

NEW “Easy Load” tub design allows faster baled intake. Takes round or square bales easily